CNC Cutting Tactics for Wood

These passages contain tactics, references, and notes for CNC operations on wood as a material. Wood is distinct from other materials in that:

- The fibers of wood make quality edge- and surface-finish difficult to achieve.

- The flat nature of wood products (boards, sheet, etc.) encourages the use of 'sheet' type tooling and workholding.

I intend for this document to become my master guide for all those little hard-to-remember details and a compendium of the methods I develop to save time and improve quality.

Thru-Cuts

By thru-cut I refer to using an end mill to cut completely to the bottom of the work. This is especially relevant for 'cookie cutter' type operations where a variety of shapes are cut from the stock by external contour. Z-level accuracy is really critical for these operations, but especially when working with wood there are some issues:

- Thickness of material can not often be known in advance with more than 0.01" accuracy.

- Thickness of material can vary (esp. for plywood).

- Material may not lay perfectly flat across the bed (esp. for thinner plywood).

- Cutting as near to the bottom of the stock as possible (to within 0.01" or lower) is necessary, but cutting too far damages the machine bed below.

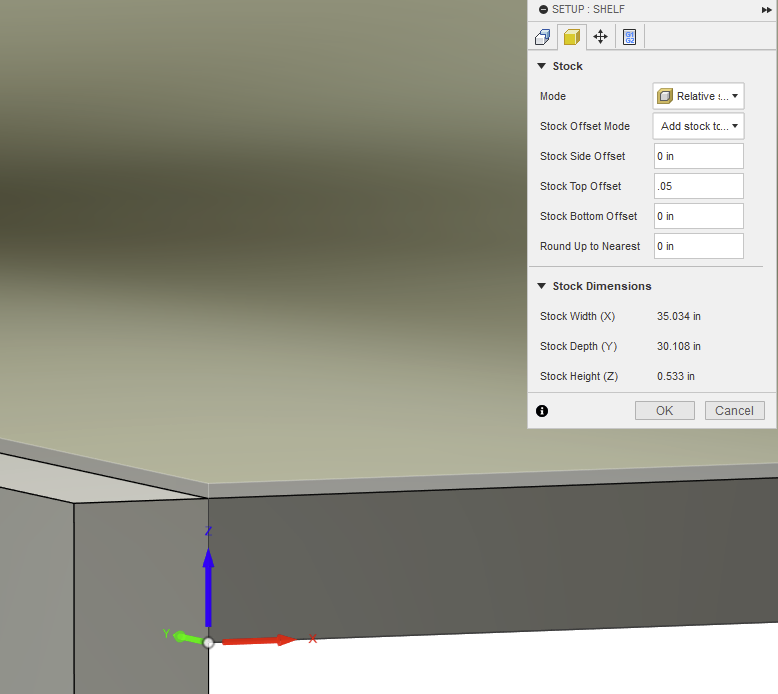

However, there is a solution to this problem. For starters, the machine should be zero'd off the bed rather than the top of the work. This ensures that accuracy is relative to the machine bed, which is the most important part. Then, add the maximum material variation to the stock top offset, so that local variations in material thickness and distance-from-bed do not cause the work to intersect with the cutter during movements. The machine will waste a little time 'cutting air' due to this offset, but that's an acceptable cost.

One must take care to note that, when using this tactic, the top surface of the material will be uneven. This means that any non-thru-cut features (like a countersink on a hole) will have varying depths relative to the bottom surface.

Tearout

Tearout occurs when a cutting edge (like a saw or endmill) is moving away from the surface of the material when it exists the material volume. The last few fibers of wood are grabbed in this motion and 'tear out' into the open air instead of cutting smoothly.

3D Geometry

This section covers situations where complex 3D surfaces are being carved with the machine.

via Ball Mill

The ball mill is a popular way to carve out geometry. The finishing pass will require some amount of 'stepdown' or 'stepover'. This sets the distance between passes. Smaller stepovers yield more passes, a better finish, and longer work times.

| Stepover | Material | Result | Image |

| 0.001" | Cherry HW | Excellent, but very slow. Certainly overkill. | Link |

Appendix I: References

- EOA Saw Manual

- Excellent overview of the factors of CNC for actual production. Not a beginner guide, so quite good. Obsessed with collets.